Here at Atlas we offer a broad variety of Wrought Alloys. Wrought Alloys under the Bronze products tab on our website are generally available in sheet/ plate, rods, tubes or bar stock. We have a great inventory selection of products that can be pulled right from our shelves.

They are typically produced by rolling and extrusion mills or by a Forging Mill. In either case the material starts out as a particular shape (i.e. Round or Square block or billet) and is then cast into the desired form by either "Extruding or Pushing" the material or by "Hammering or Forging" the material down into shape. Additionally some of our material is available in an "As cast and cold drawn condition". This process involves casting the rod and then repeatedly cold drawing it to it's final dimension and annealing it during the process when necessary. A more detailed explanation for each can be found below...

Hot Extrusion

In extrusion, a bar or metal is forced from an enclosed cavity via a die orifice by a compressive force applied by a ram. Since there are no tensile forces, high deformations are possible without the risk of fracture of the extruded material.

The extruded article has the desired, reduced cross-sectional area, and also has a good surface finish so that further machining is not needed. Extrusion products include rods and tubes with varying degrees of complexity in cross-section.

The Extrusion process allows for solids, tubes and profiles to be made. Contact one of our Sales Representatives and find out if your application, spec and material require an Extruded product.

PICTURE TAKEN FROM: http://www.doitpoms.ac.uk

Forging

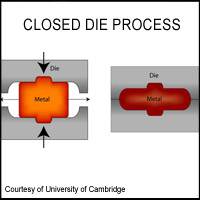

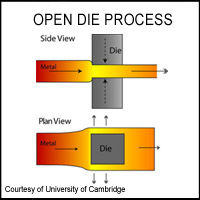

There are 2 main types of Forging methods. Closed Die Forgings and Open Die Forgings.

In Closed Die Forgings a single piece of metal, normally hot, is deformed mechanically by the application of successive blows or by continuous squeezing. A force is brought to bear on a metal slug or preform placed between two (or more) die halves. The metal flows plastically into the cavity formed by the die and hence changes in shape to its finished shape.

In Open Die Forgings the metal is between flat dies with no pre-cut profiles. The dies do not confine the metal laterally during forging. Deformation is achieved through movement of the workpiece relative to the dies.

Cold Drawn

Drawing is the pulling of a metal piece through a die by means of a

tensile force applied to the exit side. A reduction in cross-sectional

area results, with a corresponding increase in length. A complete

drawing apparatus may include up to twelve dies in a series sequence,

each with a hole a little smaller than the preceding one.

Drawing is the pulling of a metal piece through a die by means of a

tensile force applied to the exit side. A reduction in cross-sectional

area results, with a corresponding increase in length. A complete

drawing apparatus may include up to twelve dies in a series sequence,

each with a hole a little smaller than the preceding one. Cold Drawing is where one casts a Rod (solid shape) or profile first and then after a careful pre-treatment procedure and de-scaling of the bar they are drawn through a forming die. This operation is typically repeated several times.

Metals can be formed to much closer dimensions by drawing than by rolling. Drawn products include wires, rods and tubing products. Seamless tubing can be produced by cold drawing when thin walls and very accurate finishes are required. This process tightens the cross-sectional tolerances, leading to improved dimensional accuracy and surface quality.

Cold drawn material offer extensive advantages, among other things:

- Smooth and scale-free surface

- Sharp edges

- Uninterrupted grain orientation

- Increased tensile strength and yield point

Atlas Bronze offers a number of alloys Cast & Drawn. Contact one of our Sales Representatives and find out if your application, spec and material require a Cast & Drawn product.

Hot Rolling

Rolling is the most widely used deformation process. It consists of

passing metal between two rollers, which exert compressive stresses,

reducing the metal thickness. Where simple shapes are to be made in

large quantity, rolling is the most economical process. Rolled products

include sheets, structural shapes and rails as well as intermediate

shapes for wire drawing or forging. Circular shapes, ‘I’ beams and

railway tracks are manufactured using grooved rolls.

Rolling is the most widely used deformation process. It consists of

passing metal between two rollers, which exert compressive stresses,

reducing the metal thickness. Where simple shapes are to be made in

large quantity, rolling is the most economical process. Rolled products

include sheets, structural shapes and rails as well as intermediate

shapes for wire drawing or forging. Circular shapes, ‘I’ beams and

railway tracks are manufactured using grooved rolls.Initial breakdown of an ingot or a continuously cast slab is achieved by hot rolling. Mechanical strength is improved and porosity is reduced. The worked metal tends to oxidize leading to scaling which results in a poor surface finish and loss of precise dimensions. A hot rolled product is often pickled to remove scale, and further rolled cold to ensure a good surface finish and optimize the mechanical properties for a given application.

Atlas Bronze offers a number of alloys Hot Rolled. Contact one of our Sales Representatives and find out if your application, spec and material require a Hot Rolled product.

PICTURE TAKEN FROM: http://www.doitpoms.ac.uk

Good article, like it! Appreciate the patience in putting up such determined content. Thanks for the time and effort. Cast Iron

ReplyDeleteThanks for sharing the best information and suggestions, I love your content, and they are very nice and very useful to us. You can also click to know Aluminum Die Casting Companies,then visit Aluminum Die Casting. I appreciate the work you have put into this.

ReplyDeleteThanks for ones marvelous posting! I genuinely enjoyed reading it,

ReplyDeleteyou’re a great author.I will be sure to bookmark your blog

and may come back down the road. I want to encourage you continue your great work,

have a nice afternoon!

My web site; 안마

(freaky)