Are you wondering when you might need metal welding and fabrication, and why? Have you ever considered how you might use these techniques to craft an object, or refurbish a part of your home or car? Let’s start with the basics.

Welding and fabrication are two different things, although many people use both words interchangeably.

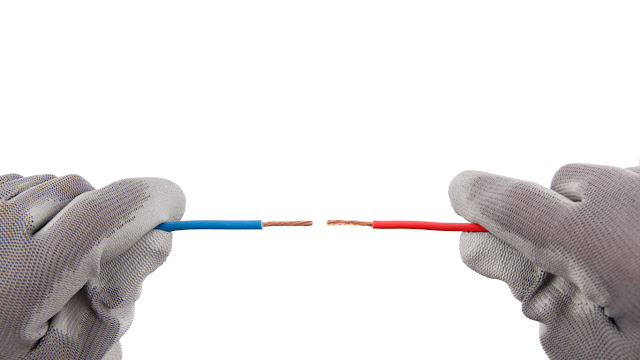

Fabrication refers to making something out of metal, while welding is simply joining two pieces of metal together at their melting points. Welding is really one step in the process of fabrication which involves laying out a design, then welding the materials and finishing the design. In short, welding is one element in a bigger process. But of course, both go hand in hand. Welders usually know how to fabricate an object, and those who fabricate know how to weld.

So let’s take a look at welding and fabrication, and what you need to do to implement these skills.

Using the Right Tools

In order to weld and fabricate, you need the right tools. These include welding items such as:

Abrasives

Benders

Electrode holders

Soapstone

Vice/vice grips

Tungsten inert gas - for clean welding

Chipping hammers

Hand File

Adjustable wrench

Additionally, important fabrication tools include:

Cleco fasteners

Angle grinder discs

Cleaning supplies are also important to remove germs, oils, and the build-up of grease on metal surfaces. To handle cleaning appropriately, you’ll need one of these three items:

Acetone

Alkaline solution (mild)

Degreaser (one that does not contain butoxyethanol)

Be sure to protect yourself and your workstation with proper cleaning and safety tools, too. Safety is essential.

For workstation cleaning:

Coverings/protection films

Mops and sweepers

For personal safety:

Flame-resistant pants

Leather apron

Boots - either non-slip or steel toe

Fume extraction tools

Working gloves

Safety goggles

Hearing protection

Respirator or dust mask

Auto-darkening helmet (with visor)

Safety must come first, so be sure you can afford to purchase and know how to use all of this equipment before getting started.

Different Types of Welding

There are a variety of different kinds of welding techniques and types that you’ll discover. Sheet metal fabrication and welding takes a series of extensive steps to fully complete. Each requires a different technique or type of welding. For example, you will likely need to perform these techniques:

Die cutting

Roll Forming

Finishing

Spinning

Shrinking

Stamping

Stretching

Welding types include:

Oxy acetylene

TIG

Gas metal arc.

MIG (Metal Inert Gas)

Conventional stick welding

One of the easiest types of welding is metal inert gas, which can be used to shape metal art. In the mainstream welding industry, TIG is frequently used, due to its ability to weld relatively devoid of splatter.

Stick welding creates very strong welds, for that reason this is the technique most often chosen for heavy repairs and for applications such as construction work.

All in all, no matter when you need to use the processes of welding or fabrication, or the reason why, you need to utilize proper safety equipment, perform correct handling practices, and be using the right tools. With all of these elements in place, welding and fabricating are skills you should be able to master in a short amount of time, and there are many opportunities in welding and fabrication in the workforce, as well as at home or in your own garage or workshop.

Learn More About Metal Welding and Fabrication

To find out more about metal welding and fabrication, or consult with us about these processes, contact us at Atlas Bronze. Call 1-800-478-0887 to speak to one of our sales representatives about our wide selection. Our team of experts will guide you through the process.