When you begin a project, there may be a perfect vision in your head, but to get it to the final stages there are a lot of decisions that need to be made to achieve the highest quality of product.

Over the years Atlas Bronze has acquired the keen knowledge of how your material is made, the lead time for the material and the ultimate cost will depend on the some of the following factors:

- Desired Alloy

- Specification (if noted)

- Size Range

- Quantity

- Lead time needed

The best way to help you determine the best fit for your needs would be to CONTACT US by either email or call 1-800-478-0887.Some of the most common methods of casting for Bronze Alloys are as follows:

Sand Casting

Sand

casting is probably the oldest method in practice. In this process the

mold is prepared using sand or silica and the molten liquid metal is

poured into it. The mold is made of two parts, the cope and the drag. A

wooden pattern is placed between these two parts, called the mold

cavity. The liquid metal enters here and casts itself. The shape of the

mold cavity is similar to the final object after the refining

Sand

casting is probably the oldest method in practice. In this process the

mold is prepared using sand or silica and the molten liquid metal is

poured into it. The mold is made of two parts, the cope and the drag. A

wooden pattern is placed between these two parts, called the mold

cavity. The liquid metal enters here and casts itself. The shape of the

mold cavity is similar to the final object after the refining Centrifugal Casting

The

Centrifugal casting process uses a mold which is fixed to a motor on an

axis to rotate it at high speeds. The speed of rotation depends on the

metal to be cast and the shape required. This method is mainly used for

the production of cylindrical components like pipes. As the motor

rotates, the metal gets pushed towards the outer walls of the cast and

solidifies. The centrifugal process is unsuitable for making

linear-shaped and dense

The

Centrifugal casting process uses a mold which is fixed to a motor on an

axis to rotate it at high speeds. The speed of rotation depends on the

metal to be cast and the shape required. This method is mainly used for

the production of cylindrical components like pipes. As the motor

rotates, the metal gets pushed towards the outer walls of the cast and

solidifies. The centrifugal process is unsuitable for making

linear-shaped and dense objects.

Continuous Casting

Continuous

casting, as the name implies, converts molten metal into a continuous

moving ingot shape with a rectangular or round cross section. Time,

energy, and labor are saved. Generally, a water-cooled mold is employed,

receiving molten metal in one end and delivering a continuous

solidified product out the other. The molds can be vibrating or moving,

slow or fast.

Continuous

casting, as the name implies, converts molten metal into a continuous

moving ingot shape with a rectangular or round cross section. Time,

energy, and labor are saved. Generally, a water-cooled mold is employed,

receiving molten metal in one end and delivering a continuous

solidified product out the other. The molds can be vibrating or moving,

slow or fast.Atlas offers high quality Sand Casting, Centrifugal Casting, and Continuous Cast products at competitive prices and great lead times. Your alloy, specification or application might indicate the part needs to be made as any one of the listed methods. Speak to one of our Sales Representatives to determine if your application should be made as a Continuous, Centrifugal or Sand Casting product.

For more information or to see what else we could do to help, please visit our website at www.atlasbronze.com.

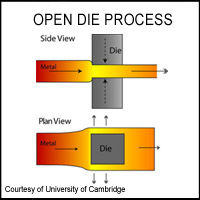

Drawing is the pulling of a metal piece through a die by means of a

tensile force applied to the exit side. A reduction in cross-sectional

area results, with a corresponding increase in length. A complete

drawing apparatus may include up to twelve dies in a series sequence,

each with a hole a little smaller than the preceding one.

Drawing is the pulling of a metal piece through a die by means of a

tensile force applied to the exit side. A reduction in cross-sectional

area results, with a corresponding increase in length. A complete

drawing apparatus may include up to twelve dies in a series sequence,

each with a hole a little smaller than the preceding one.  Rolling is the most widely used deformation process. It consists of

passing metal between two rollers, which exert compressive stresses,

reducing the metal thickness. Where simple shapes are to be made in

large quantity, rolling is the most economical process. Rolled products

include sheets, structural shapes and rails as well as intermediate

shapes for wire drawing or forging. Circular shapes, ‘I’ beams and

railway tracks are manufactured using grooved rolls.

Rolling is the most widely used deformation process. It consists of

passing metal between two rollers, which exert compressive stresses,

reducing the metal thickness. Where simple shapes are to be made in

large quantity, rolling is the most economical process. Rolled products

include sheets, structural shapes and rails as well as intermediate

shapes for wire drawing or forging. Circular shapes, ‘I’ beams and

railway tracks are manufactured using grooved rolls.